Processing3D Slip Casting®

Original developed method based on Pottery slipcast method.

- HOME

- Technology

- 3D Slip Casting®

What's "3D Slip Casting ®" method?

The original method of KDA

The 3D Slip Casting® method is a ceramic manufacturing method which has been developedby KDA corporation.

This method commercializes new ceramics production (complicated shapes, low price and rapid delivery.) which was once considered impossible with the existing technology.

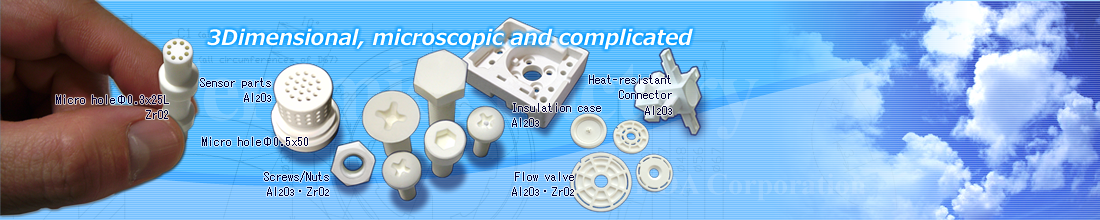

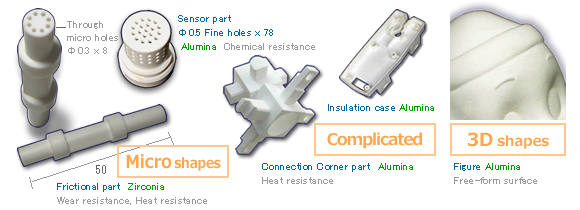

3D Slip Casting® method can make such shapes.

This method is valid for making complicated, micro and 3 dimensional shapes. With existing technologies, cutting block and molding etc, it is so hard to make such ceramic shapes or is impossible.

Reason to be superior making Micro, Complex, 3D shapes.▶

As other features than making such shapes above, there are availabilities in prices and delivery time.

One 10th cost of the past! Making by inexpensive price.

Ceramic materials have some difficult points to make products, hard to make precisely for the nonuniform contraction after firing, hard to cut for the hardness, easy to occur a clack in cutting or firing.

That's really hard to make and hard to get uniformity products. Therefore however the unit price becomes high in comparision with other materials (metals and plastics).

And by molding, the metal precision molds are high cost. So a product price becomes high.

But this 3D Slip Casting® pulls down the cost to one 10th of existing method.

Reason to make by low cost 1/10 of the past..▶

Shortest 20 days! Quick delivery.

As metioned above, manufacturing of ceramics parts spends raborious process compared with other materials. Therefore the delivery time usually takes more than 1 month. But by 3D Slip Casting® method, it takes 20days in the shortest.

Reason for short delivery 20 days.▶

Suitable for Small lot and Prototype.

In case of small lot or prototype, generally everyone has an image of higher cost to make ceramics parts, because ceramics are more difficult to process than other materials.

But our 3D Slip Casting® method is suitable for small lot or one pice order, and furthermore it can make by economical price.