Processing3D Slip Casting® - details

Original developed method based on Pottery slipcast method.

- HOME

- Technology

- 3D Slip Casting®

- Detail

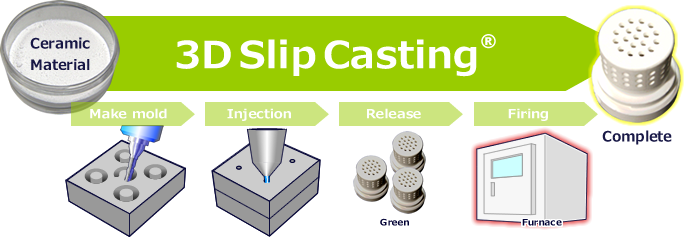

Outline of 3D Slip Casting® method

| Material | Make slurry from granular material of Alumina or Zirconia. | Making mold | Do not use precision metal mold, but use plastic or other materials. And cut them by machining to make a mold. |

|---|---|

| Injection | Inject slurry to the mold. |

| Release | After slurry bind by drying, it release from the mold and be a green. |

| Firing | Do under controlled environment of temperature and time. |

| Complete | Take sintered bodies (products) out from the furnace. |

Point1 No use expensive precision metal mold.

Do not use expensive precision metal mold, if not in case of mass production of simple shapes.

Use various materials for the molds.

According to shape and quantity of part you demand, we select materials out of metals to make molds. For example, there are cases of using various plastics, wax or other materials.

Make a mold by simple process and free style.

We pursue better material or method which can make complicated, micro or 3 dimensional shapes as simply as possible.

If you provide 3D data, we can make various shapes by consideration of the contraction based on each ceramic materials.

In case of complicated shape which can not be made by any machinings, we have used rapid-prototyping or 3D printer.

Point2 No machining process.

No cutting process before and after the firing.

In the process (Molding ▶ Firing ▶ Complete), there is no cutting of any green or sintered body. But keep some degree of precision. (* We recommend precision machining processing when you need more than 1/100.)

To realize this, we've controled the process from mixing materials to molding and firing closely.

Merits of 3D Slip Casting® method. (summary)

Low price and short delivery Because of no metal mold and cutting.

Do not use a precision metal mold, but use various materials except metals to make molds, for example plastics. Before or after firing process, do not cutting and grinding. Therefore it is possible to provide by low price and short delivery (minimum 20 days).

Small lot Suitable for prototypes or small lot, because of low price.

The establishment of manufacturing at low cost is effective in scenes, small lot or prototyping. You can order ceramic products easily.

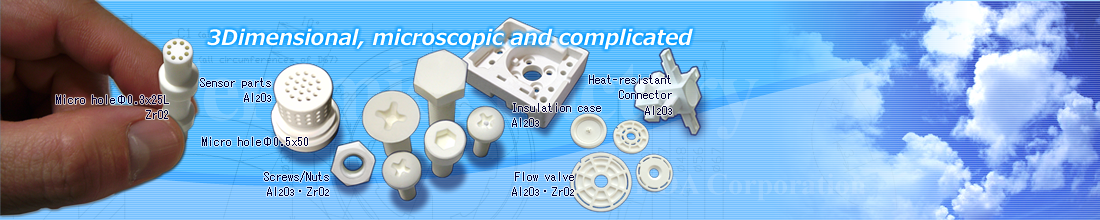

Complex, Micro, 3D shapes Meet various shapes you demand!

For realizing various shapes you need, we utilize all materials available as molds.