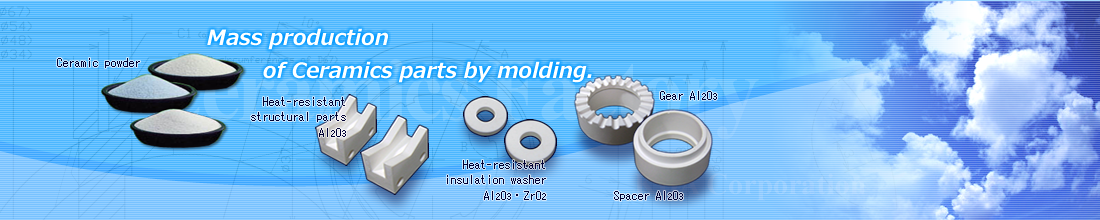

ProcessingMolding

Various molding services to meet the needs for mass production of ceramic parts.

- HOME

- Technology

- Molding

Various technologies of Ceramic molding.

| Press molding | Inject ceramics slurry materials to a mold, compress and fire it. Features: suitable for mass-productions of simple and high precision shapes. |

|---|---|

| Extrusion molding | Extrude ceramics paste to a die (mouthpiece), and get shapes of which section is circle, polygon, pipes etc continuously. |

| Tape molding | Makes Alumina thin plate for IC substrate etc. |

Products

We deal in general ceramic materials such as Alumina (Aluminium Oxide) and Zirconia (Zirconium Oxide). And deal in Steatite, Cordierite and Forsterite etc too. We make shapes from these ceramics powder, fire them and complete.

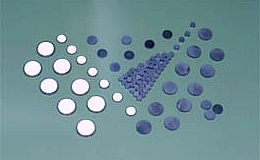

General ceramic electrical parts

Use the electrical insulation in high thermal environment and the high frequency property, makes ceramic parts which is superior to mechanical strength, thermal-shock and wide-use.

Ceramic Precision parts

For making precision parts (precision jig, mechanical sliding parts etc), it is needed high accuracy dimensional technology. So we do cutting process by machine after molding, and after firing, do grinding or polishing.

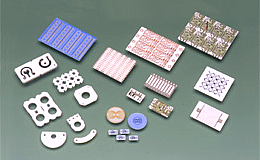

Semiconductor Ceramic parts

These are usable widely as IF circuit or HIC of various electrical equipments.

Ceramic thin plate printed circuit

A printed circuit board is made by pressing or tape-forming a thick film board, printing various metal pastes on it, and sintering it. These are used for HIC, various resistance boards, heater boards, etc.

Grass seal component

Seal and bond ceramic and metal using glass. It can be used for a wide range of electronic tubes, stems such as heaters, and various airtight terminals.